Services

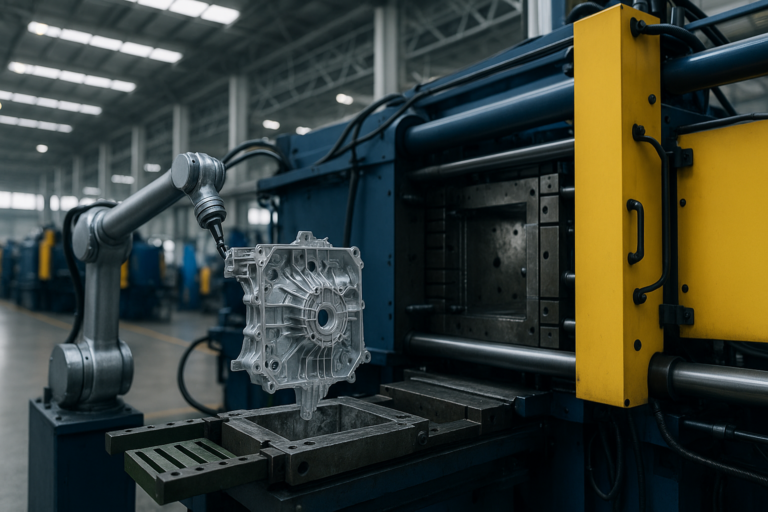

End-to-End Die Casting Services

Precision engineered components with industry-leading quality and cost efficiency

70% Supply Chain Simplification

Streamlined processes from concept to delivery

30% Quality Cost Reduction

Superior precision with lower overall costs

Real-Time Process Tracking

Monitor your project status at every stage

Die Casting Solutions Overview

Your comprehensive partner for precision die casting services from concept to completion.

Value Proposition

One-stop die casting service from design to delivery, reducing your supply chain complexity by 70%

Comprehensive solution integrating design, mold, manufacturing, machining, and surface treatment with a single point of contact

Service Advantages

Combination of precision control and innovative processes that make your product performance exceed industry standards

Proprietary technology reduces common die casting defects by 30%, saving you quality costs and market risks

Service Process Diagram

Initial Consultation

Thorough analysis of your requirements and project specifications to establish clear objectives.

Material Selection

Expert material selection and engineering design optimized for die casting production.

Mold Design & Manufacturing

Precision mold creation using advanced CAD/CAM technology for optimal casting results.

Sample Validation

Rigorous testing and validation of sample products to ensure they meet all specifications.

Mass Production

Efficient mass production with comprehensive quality control at every stage.

Secondary Processing & Delivery

Final finishing, packaging, and timely delivery to your specified location.

Frequently Asked Questions

Answering customer's most concerned questions about delivery time, quality, cost, minimum order quantity, etc. Our answers are supported by real cases and data to help you make informed decisions.

4-6 weeks for mold creation and 2-3 weeks for production. Expedited services available for time-sensitive projects.

500 units standard MOQ, 300 for complex parts. Flexible solutions for prototyping and small batch production.

Comprehensive quality management system with material certification, in-process inspections, and final checks using advanced measurement equipment.

Material selection, part complexity, surface finish, tolerance specifications, quantity, and secondary operations. We provide transparent pricing and cost optimization suggestions.

High Pressure Die Casting Services

Our comprehensive high-pressure die casting solutions deliver precision, efficiency, and superior mechanical properties for your most demanding applications.

Technical Overview & Advantages

Clamping force up to 4,000 tons enabling high-precision forming of large components

High-speed, high-pressure injection process ensuring dense structure and superior mechanical properties

Application Areas & Case Studies

Ideal process for automotive structural parts, electronic heat sinks, and industrial components

Customer Success Story

Single die-cast part replaced 23 assembly components, reducing costs by 65%

Technical Parameters & Equipment

| Parameter | Aluminum Alloys | Zinc Alloys | Magnesium Alloys |

|---|---|---|---|

| Available Alloys | ADC12, A380, AlSi9Cu3, AlSi10Mg | ZA8, ZAMAK3, ZAMAK5 | AZ91D, AM50A, AM60B |

| Weight Range | 10g - 15kg | 5g - 10kg | 10g - 12kg |

| Wall Thickness | 0.8mm - 6mm | 0.5mm - 4mm | 1.0mm - 5mm |

| Tolerance Capability | ±0.05mm | ±0.04mm | ±0.06mm |

Industry Applications

Automotive

Engine blocks, transmission cases, structural components

Electronics

Heat sinks, enclosures, component housings

Medical

Equipment housings, diagnostic device components

Industrial

Pump components, valves, machine parts

Service Advantages

Advanced simulation software for optimizing mold design and process parameters

Vacuum-assisted systems for reduced porosity and improved structural integrity

Comprehensive in-process monitoring ensuring consistent quality and traceability

In-house heat treatment and finishing operations providing full control over quality

Ready to optimize your die casting project?

Our engineering team provides free design for manufacturability analysis to ensure optimal results.

Metal Injection Process

Advanced manufacturing solutions for precision metal components with industry-leading technology and quality control.

Process Types in Detail

Technical Segmentation for Various Needs

Hot Chamber Die Casting

-

15-25 second cycles, suitable for zinc, magnesium, and lead alloys

-

Strong capability for fine detail replication and high surface finish

Cold Chamber Die Casting

-

Up to 4,500 psi pressure, suitable for aluminum and copper alloys

-

Excellent strength and dimensional stability for load-bearing parts

Squeeze Casting Process

-

Combines casting and forging, achieving near-zero porosity

-

Ideal for high-performance, safety-critical components

Semi-Solid Metal Casting

-

Controls metal slurry flow, reduces gas porosity and shrinkage

-

Perfect for complex thin-walled structures, improving fatigue life by 40%

Process Parameter Control Systems

-

Precise process control system, real-time monitoring of 17 critical parameters

-

AI-assisted parameter optimization, automatic adjustment and recording

Quality Control Measures

-

Multi-stage quality inspection, full process monitoring from raw materials to finished products

-

Online X-ray detection and thermal imaging analysis for early identification of issues

Process Selection Guide

Customer Decision Support Tool

-

Interactive process selector recommending optimal processes based on your specific application requirements

-

Comprehensive consideration of materials, performance requirements, cost targets, and production scale

Mold Design & Engineering

Advanced solutions for precision die casting with industry-leading technology and expertise

Design Capabilities & Tools

Advanced CAD/CAM Systems & Flow Analysis

Utilizing industry-leading software including Solidworks and MAGMASOFT to accurately predict and eliminate potential defects

Die Optimization Process

Efficient Die Solutions that reduce total cost of ownership

Digital simulation for optimizing gating systems, extending tool life by 35% and reducing maintenance frequency by 50%

Seamless Design-to-Production

Integrated engineering process eliminating communication barriers

BOM collaborative management system ensures perfect translation of design intent to finished product, improving first-time success rate by 40%

Rapid Tool Development

Rapid tooling technology shortens standard development cycles by 45%

Special channel for urgent projects, delivering sample molds in as few as 7 days

Tool Life Management

Preventive maintenance programs extending die life and reducing long-term costs

Tool performance tracking system predicts maintenance needs and reduces downtime

Advanced Technology

Our state-of-the-art facilities equipped with the latest in mold design and engineering technology

Production & Manufacturing Excellence

Our comprehensive die casting capabilities deliver precision, flexibility, and reliability to meet your most demanding manufacturing requirements.

Production Capabilities & Equipment

-

Efficient Die Casting Production Lines enabling stable high-volume production

-

400-1600 ton pressure range satisfying full-size requirements from tiny precision parts to large structural components

Flexible Production Systems

-

Quick changeover design minimizes tool replacement time, improving efficiency for multi-variety production

-

Modular setup allows parallel production of different parts, meeting diverse requirements

Quality Management Systems

-

Full-process Quality Tracking with 100% traceability ensures rapid problem identification and resolution

-

Digital quality tracing system from raw materials to finished products, supporting your compliance requirements

Precision Tolerances & Performance

-

Micron-level Precision Control meeting high-precision assembly requirements

-

±0.05mm tolerance capability ensuring perfect fit and function for complex components

Delivery Cycles & Flexibility

-

Flexible Batch & Quick Delivery from small prototype runs to large-scale production

-

4-6 week delivery for standard parts, expedited channel service for urgent orders

Inventory Management Solutions

-

Vendor Managed Inventory (VMI) system optimizes stock based on your production schedule

-

Kanban system and JIT delivery options reducing your inventory costs and storage space

Secondary Operations & Value-Added Services

Comprehensive post-processing solutions to enhance your die casting products with precision and quality.

CNC Precision Machining

-

3-5 axis CNC machining centers for high-precision complex features

-

Tolerance control up to ±0.01mm for precision fitting requirements

Surface Treatment

-

Complete surface treatment solutions for aesthetics, functionality, and durability

-

Multiple options including anodizing, powder coating, electroplating, and anti-corrosion treatments

Heat Treatment

-

Customized heat treatment solutions to optimize metal properties for specific applications

-

T5, T6 heat treatment processes to improve strength, hardness, and durability

Assembly & Integration

-

Component-to-product assembly to reduce your supply chain steps

-

Insert injection, thread processing, sealing treatment, and other functional integrations

Packaging & Logistics

-

Custom protective packaging to ensure safe product transportation

-

Global logistics solutions for seamless delivery from our factory to your production line

Threading & Inserts

-

Precision threading operations for all standard thread sizes and custom specifications

-

Insert molding and post-casting insert installation for enhanced functionality

Technical Consultation Services

Expert guidance to optimize your die casting projects, enhance performance, and reduce costs

Design Optimization Consultation

Die casting design optimization recommendations to improve performance while reducing costs

Expert analysis of your designs, providing feasible improvement solutions that reduce weight by an average of 25% while improving performance by 15%

Application-based Alloy Selection

Alloy selection recommendations based on application requirements

Comprehensive consideration of strength, weight, thermal conductivity, cost and other factors to recommend the optimal material solution

Comprehensive Cost Optimization

Complete cost optimization analysis to identify potential savings

Evaluation from design, materials, processes, post-processing and other aspects to provide implementable cost reduction strategies

Manufacturability Assessment

Die casting feasibility evaluation to identify and resolve potential issues in advance

Detailed analysis of whether your design is suitable for die casting processes, preventing unexpected challenges during production

Expert Failure Analysis

Professional fault analysis and solutions

Material testing, structural analysis, performance evaluation to find root causes and provide improvement recommendations

Innovation Consulting

Advanced die casting technology and innovation solutions

Guidance on implementing cutting-edge die casting technologies and innovative approaches to improve product performance and manufacturing efficiency

Need Specialized Technical Support?

Our team of die casting experts is ready to help you optimize your projects, solve technical challenges, and improve your production efficiency.

Innovation & R&D Services

Elevating your products with cutting-edge research and development solutions that drive competitive advantage.

Lightweighting Solutions

-

Special alloy and structural optimization technologies, achieving 30-50% weight reduction

-

Topology optimization design combined with high-strength alloys, maintaining or improving performance

Multi-Material Integration

-

Innovative combination of metal and non-metal materials, achieving functional integration and cost optimization

-

Insert molding, composite material combination, and dissimilar metal joining technologies

Advanced Surface Treatment

-

Customized surface treatment solutions meeting special application requirements

-

Innovative technologies including nano-coatings, plasma treatments, and biomimetic surface designs

Prototype Validation Services

-

Rapid prototype creation and validation, accelerating product development cycles

-

Full-process support from 3D printed validation models to functional die-cast prototypes

Our engineering team is ready to collaborate on your next innovation challenge