Auto DieCasting Solutions for High-Performance Automotive Parts

Precision aluminum, zinc, and magnesium die castings for structural, powertrain, EV, and interior automotive components.

From DFM to tooling, die casting production, CNC machining, surface finishing, and assembly — automotive die casting solutions engineered and manufactured by IEC MOULD to meet global OEM and Tier 1 standards.

Auto Die Casting in the Automotive Industry: Trends, Challenges & Solutions

The die casting in the automotive industry has evolved rapidly to meet the demands of lightweight structures, complex geometries, and high reliability. Automotive OEMs and Tier 1 suppliers increasingly require high-precision automotive die castings with zero-defect rates, stable batch production, and full traceability.

With the rise of EVs and new energy vehicles, the demand for automotive aluminum die casting and magnesium die casting for lightweight components continues to grow.

At IEC MOULD, these automotive die casting requirements are addressed through engineering-driven DFM, controlled tooling design, and stable mass production, ensuring every component — from structural brackets to battery housings — meets stringent automotive standards.

Automotive Castings & Die Casting Automotive Parts We Produce

These automotive castings are produced through controlled auto die casting processes applied in IEC MOULD’s automotive programs.

Structural & Safety-Critical Components

Body brackets, suspension components, chassis supports. Made with aluminum or magnesium alloys for strength and lightweight optimization

Powertrain & Transmission Components

Engine housings, gearbox housings, transmission covers High precision, thermal stability, and dimensional accuracy

EV Components

Electric motor housings, inverter enclosures, battery boxes Lightweight alloys, heat dissipation solutions, long-term durability

Interior & Functional Parts

Door lock components, handles, decorative interior trims Zinc and aluminum alloys for precision and smooth surface finishes

Materials for Automotive Die Casting Components

Selecting the right material is critical in automotive die casting, directly impacting part strength, weight, thermal performance, corrosion resistance, and long-term reliability. IEC MOULD applies application-driven material selection to ensure each automotive die cast component meets functional, structural, and lifecycle requirements across OEM and Tier 1 programs.

Aluminum Die Casting for Automotive components

Commonly used aluminum alloys in automotive casting include

- ADC12

- A380

- A356

- AlSi9Cu3

Key advantages:

- Lightweight properties supporting vehicle weight reduction

- High strength and stiffness for load-bearing applications

- Excellent corrosion resistance for long-term durability

- Superior thermal conductivity for heat dissipation in powertrain and EV components

These alloys are extensively used in automotive aluminum die casting for engine housings, transmission cases, structural brackets, and EV battery enclosures.

Zinc Die Casting for Automotive components

These zinc allows widely used in automotive zinc die casting where high dimensional accuracy and surface quality are required.

- Zamak 3

- Zamak 5

Key advantages:

- Thin-wall precision for complex and compact designs

- Smooth surface finishes, ideal for visible and functional parts

- Excellent repeatability and consistency in high-volume production

Zinc alloys are commonly applied to interior components, door lock mechanisms, handles, and other high-precision die cast parts in automotive applications.

Magnesium Die Casting for Automotive Parts

Magnesium die casting is increasingly adopted in EVs and premium vehicles as part of the global lightweighting strategy in the automotive parts magnesium die casting market.

Key advantages:

- Exceptional strength-to-weight ratio for aggressive weight reduction

- Excellent thermal management for electric and electronic components

- Effective vibration damping, improving NVH performance

Magnesium alloys are particularly suitable for EV motor housings, structural supports, and integrated functional parts where reducing mass without compromising performance is critical.

Automotive Foundry & Precision Tooling Capabilities

In automotive die casting, tooling quality and process stability directly determine part consistency, cost efficiency, and long-term program success. As a professional automotive foundry, IEC MOULD integrates in-house tooling design, precision mold manufacturing, and process validation to support stable, high-volume auto castings for global OEM and Tier 1 programs. Our tooling systems are developed with a clear focus on long-term automotive production, combining mold lifetime, process repeatability, and application-specific design requirements to ensure consistent performance throughout the entire program lifecycle.

Engineering-Driven Tooling & Mold Design

Tooling for automotive die casting must accommodate complex geometries, tight tolerances, and extended production lifecycles. IEC MOULD’s tooling solutions are engineered to meet these requirements through a validated, simulation-driven approach.

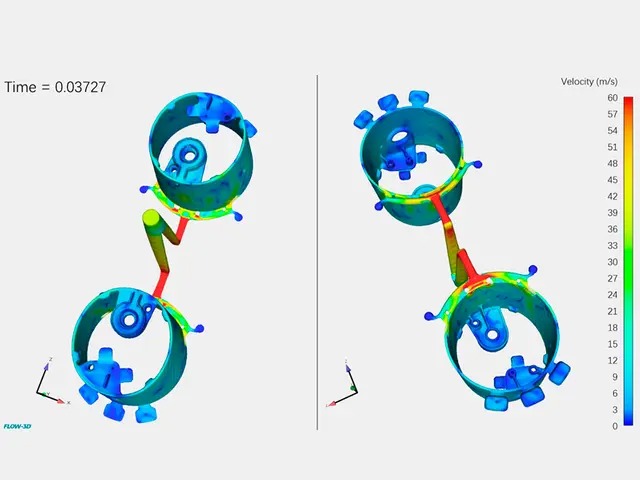

- Moldflow simulation and design optimization to verify filling, cooling, and solidification behavior prior to tooling release

- High-lifetime molds, typically supporting 100,000 to 500,000+ shots, designed for long-term automotive production programs

- Complex slides, lifters, and core pull mechanisms enabling intricate geometries and integrated functional features

- Optimized gating and venting systems to minimize porosity and ensure structural integrity of automotive die cast parts

These tooling strategies ensure dimensional stability, structural reliability, and repeatable quality across a wide range of automotive die casting applications.

Process Stability for High-Volume Auto Castings

In high-volume automotive die casting, consistent quality depends on repeatable tooling performance and tightly controlled process parameters.

IEC MOULD designs tooling and processes with stability as a core objective, supporting automotive programs from initial sampling through mass production.

- Tooling and process designs focused on batch-to-batch consistency for large-scale automotive programs

- Stable dimensional control to maintain tight tolerances in high-volume auto castings

- Reduced scrap rates and improved production efficiency, supporting cost-sensitive and long-term automotive projects

Through controlled tooling execution, in-house validation, and trial production, IEC MOULD ensures automotive die cast components remain consistent from first-off samples to full-scale mass production, meeting OEM and Tier 1 quality and reliability expectations.

Auto Die Casting Process for Automotive Components

Automotive die casting requires more than just forming metal parts — it demands a controlled, repeatable process that ensures dimensional accuracy, structural integrity, and long-term production stability. The following auto die cast process reflects how precision die casting for the automotive industry is executed from early engineering validation through mass production.

DFM & Engineering Review

Design for Manufacturing (DFM) analysis is conducted to evaluate wall thickness, ribs, draft angles, and metal flow paths. This step ensures part functionality, manufacturability, and cost efficiency while minimizing potential defects in automotive die casting.

Moldflow Analysis & Simulation

Moldflow simulation is used to analyze metal filling, cooling, and solidification behavior. Potential risks such as air entrapment, porosity, and shrinkage are identified and optimized before tooling release, improving first-time success in auto die cast production.

Tooling Design & Manufacturing

Moldflow simulation is used to analyze metal filling, cooling, and solidification behavior. Potential risks such as air entrapment, porosity, and shrinkage are identified and optimized before tooling release, improving first-time success in auto die cast production.

Tooling Validation & Trial Production

Trial runs and sample validation are performed to verify dimensional accuracy, surface quality, and process stability. Adjustments are completed before mass production to ensure reliable precision die casting for automotive industry applications.

High-Pressure / Low-Pressure Die Casting

Depending on part geometry and material requirements, high-pressure or low-pressure die casting processes are applied. These controlled casting methods achieve tight tolerances, dense structures, and the mechanical integrity required for automotive components.

CNC Machining & Precision Finishing

Critical features, interfaces, and tolerance-sensitive areas are CNC machined to achieve dimensional accuracy up to ±0.01 mm, ensuring proper fit, sealing, and functional reliability in automotive assemblies.

Surface Treatments & Protective Coatings

Automotive-grade surface treatments such as powder coating, anodizing, plating, and brushing are applied to enhance corrosion resistance, wear performance, and visual quality.

Assembly & Final Inspection

Final assembly and inspection include leak testing, CMM measurement, X-ray inspection, and functional testing. Only automotive die cast components that meet defined quality standards proceed to delivery.

Why Choose Our Auto Die Casting Solutions

Automotive programs demand more than manufacturing capacity — they require engineering-driven execution, process stability, and long-term supply reliability.

Our automotive die casting solutions are designed to support OEM and Tier 1 programs from early development through high-volume production.

One-Stop Automotive Die Casting Execution

We provide a fully integrated auto die cast solution covering the entire production lifecycle:

- DFM

- Tooling

- Die Casting

- CNC Machining

- Surface Finishing

- Assembly

This one-stop approach reduces supply chain complexity, shortens lead times, and ensures consistent quality across all die cast parts.

Auto DieCasting FAQs

What are the advantages of automotive die casting?

Automotive die casting enables high-volume production with excellent dimensional accuracy, structural integrity, and surface finish.

Materials like aluminum, zinc, and magnesium allow for lightweight yet strong components, ideal for structural, powertrain, and EV applications.

At IEC MOULD, we combine engineering-driven DFM, precision tooling, and validated processes to maximize performance and reduce defects across all die casting automotive parts.

How are die cast parts inspected for quality?

Quality control in automotive die casting includes CMM measurement, X-ray inspection, leak testing, and functional checks.

IEC MOULD ensures full traceability and compliance with IATF 16949, PPAP, and APQP standards, delivering consistent, high-quality auto die cast parts for OEMs and Tier 1 programs.

Can you support high-volume automotive die casting programs?

Yes. IEC MOULD is equipped for high-volume production, maintaining batch-to-batch consistency, tight tolerances, and repeatable quality.

Our tooling, mold design, and production processes are optimized to scale while controlling cost and minimizing scrap rates.

What materials are commonly used in automotive aluminum die casting?

Common alloys include ADC12, A380, A356, and AlSi9Cu3 for structural and functional components, while zinc and magnesium alloys are used for precision parts and lightweight EV applications.

IEC MOULD selects materials based on mechanical performance, thermal management, and long-term reliability, ensuring each component meets OEM requirements.

How do you ensure traceability in the automotive die cast industry?

Full material and process traceability is maintained for every batch.

IEC MOULD implements IATF 16949-compliant systems, tracking molds, material batches, process parameters, and inspection records to ensure compliance, repeatability, and accountability for all automotive die casting solutions.

Start Your Automotive

Die Casting Project Today

IEC Mould supports from early engineering to mass production. To get started, simply send:

- 2D/3D files

- Estimated annual volumes

- Key requirements