For engineers and procurement specialists in high-stakes industries like automotive, aerospace, and consumer electronics, accurately evaluating magnesium die casting cost is a strategic decision that must be rooted in Total Cost of Ownership (TCO), not just the initial quote. Historically viewed as a premium option, magnesium alloy is now at a tipping point. Driven by material price reversals and manufacturing advancements, it presents a compelling value proposition that extends far beyond price-per-kilogram.

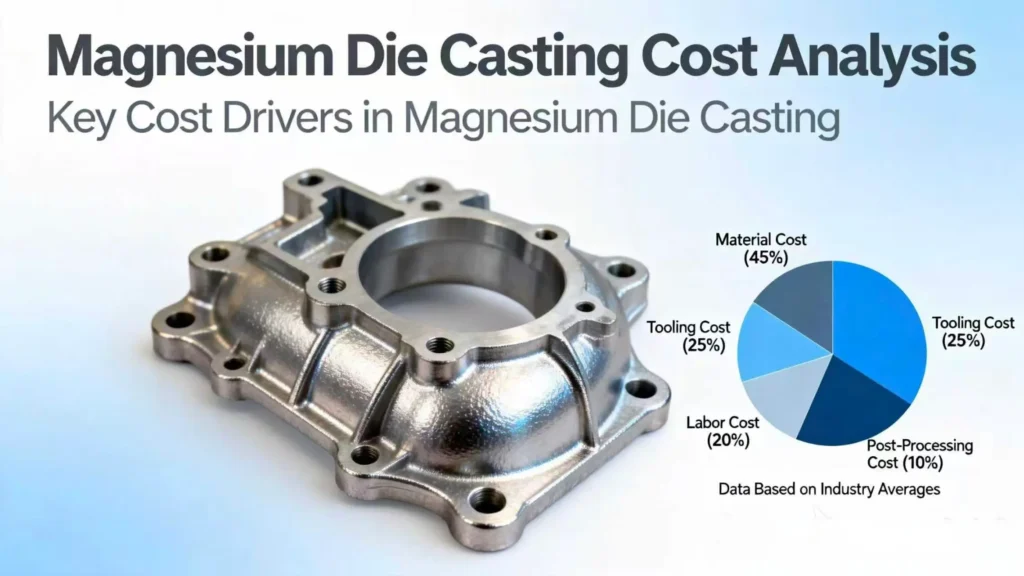

The Visible Cost Breakdown – Deciphering Your Quote

A professional quote transparently itemizes costs. Understanding each element is the first step to a fair comparison.

Material Cost: The Foundation of Magnesium Die Casting Pricing

- 2026 Price Data: As of 2026, the average price for magnesium ingot is competitive, often trading at or even below the price of aluminum alloy ingots on a per-kilogram basis.

- Volumetric Advantage: This is critical for lightweighting. Magnesium’s density (1.74 g/cm³) is 36% lower than aluminum’s (2.70 g/cm³). This means you use less material by volume to produce a component of similar size. This volumetric advantage means the material contribution to the overall magnesium die casting cost can be significantly lower than often assumed.

Tooling & Mold Cost: The Foundation of Quality and Consistency

- Simple Molds: For basic components, mold costs can range from $5,000 to $15,000.

Complex Molds: For parts with undercuts, multiple slides, or intricate cores, costs can escalate to $80,000 – $150,000+.

Processing & Manufacturing Cost

- Machine Hourly Rate: Die casting machines are categorized by clamping force (tons). Larger parts require larger, more expensive machines.

- Cycle Time: Faster cycle times lower the cost per part. Magnesium’s excellent fluidity can sometimes lead to faster fill times compared to aluminum.

- Energy & Safety: Traditional magnesium die casting requires a protective atmosphere (like SF₆ mix) to prevent molten metal oxidation, adding to operational cost. However, advanced processes like semi-solid die casting (thixo-molding) operate at lower temperatures (~580°C vs. ~660°C for aluminum), drastically reducing oxidation risk and the need for expensive cover gases.

The "Hidden Cost Killers" You Can't Ignore

These factors are often omitted from initial quotes but are critical to understanding the true total cost, severely impacting the budget and timeline.

Is Your Design Increasing Your Magnesium Die Casting Cost?

- Multiple mold revisions and extended sampling cycles.

- Engineering change orders (ECOs) and project delays.

- Delayed time-to-market which can be the costliest factor of all.

▶️ Pro Tip: Engage with a supplier that offers comprehensive DFM analysis upfront. This co-engineering phase is crucial for identifying and eliminating potential issues before tooling begins, saving time and money.

The High Cost of Inconsistent Quality and Low Yield

Quality fluctuations are a silent budget drain. Inconsistent process control leads to high scrap and rework rates, which waste material, machine time, and labor. It also increases inspection overhead and risks supply chain disruption. Advanced processes like semi-solid molding are renowned for producing parts with very low porosity, directly boosting yield rates. A higher first-pass yield means a lower effective cost per good part.

Secondary Processing & Finishing Costs

- Trimming & Machining: Magnesium is generally easier to machine than aluminum, potentially reducing tool wear and machining time.

- Surface Finishing: Magnesium may require specific, sometimes more expensive, coatings for corrosion protection depending on the application environment. An integrated manufacturer who handles these stages in-house can optimize the entire workflow, reducing logistics and overall cost.

The Long-Term Value Proposition - Calculating the True ROI

This is where the analysis must shift from the initial magnesium die casting cost quote to calculating its long-term value and true Total Cost of Ownership (TCO). The long-term benefits often justify and surpass the initial investment.

Lightweighting Value: The Performance Multiplier

- For Electric Vehicles (EVs): Directly extends driving range. A 10% reduction in vehicle weight can improve energy efficiency by 6-8%. This can allow for a smaller, less expensive battery pack for the same range—a massive cost saving.

- For Aerospace & Consumer Electronics: Lighter products mean lower shipping costs, improved fuel efficiency, and enhanced portability.

- For Dynamic Components, reducing rotational mass (e.g., in e-drive housings) improves acceleration and handling, while also reducing wear on related components.

Performance & Assembly Advantages

- Superior Damping Capacity: Magnesium absorbs vibration and noise significantly better than aluminum, leading to quieter, higher-quality end products.

- Excellent EMI Shielding: Naturally provides shielding against electromagnetic interference, crucial for electronics housings.

- Part Consolidation: Large, complex magnesium castings can replace multiple assembled parts, significantly reducing the number of assembly steps, fasteners, and potential failure points.

Lifecycle & Sustainability Value

- Durability: Excellent impact and dent resistance can lower warranty and replacement costs.

- Sustainability Credentials: Using lightweight magnesium contributes to lower lifetime carbon emissions of the end product. This is increasingly valuable with regulations like the EU’s Carbon Border Adjustment Mechanism (CBAM).

- Recyclability: Magnesium is 100% recyclable with very high energy efficiency. A closed-loop recycling system can further reduce lifecycle costs and environmental impact.

| Cost Factor | Aluminum Bracket | Magnesium Bracket | Notes |

|---|---|---|---|

| Initial Part Cost | $15.00 | $18.00 | Magnesium tooling/material may be higher initially. |

| Weight per Part | 1.0 kg | 0.64 kg | 36% weight reduction. |

| Estimated Energy Savings (EV) | - | $12.50 | Calculated over vehicle lifespan. |

| Reduced Assembly Cost | $5.00 | $2.00 | Magnesium allows for part consolidation. |

| Total 5-Year Cost (per part) | $20.00 | $7.50 | Magnesium shows significant long-term savings. |

Note: This table is illustrative. Actual savings depend on application, volume, and design.

Key Questions to Ask Your Magnesium Die Casting Supplier

Move the conversation from “What is the price?” to “What is the total value?”. Ask potential partners:

DFM & Technology

“What is your DFM process? Do you use simulation software? Do you offer advanced processes like semi-solid molding for higher integrity?”

Quality & Yield

“What are your typical first-pass yield rates for similar components? What is your process control methodology (SPC, X-ray inspection)?”

Vertical Integration

“Which secondary processes (machining, coating) do you handle in-house? How does this impact cost and lead time?”

Experience & Partnership

“Can you provide case studies showing long-term cost savings for your clients? How do you engage in continuous improvement?”

FAQ

How does the total magnesium die casting cost compare to aluminum when considering TCO?

When evaluated solely on the initial quote, magnesium die casting cost may appear higher. However, the Total Cost of Ownership (TCO) is often lower due to magnesium’s superior lightweighting, which leads to significant savings in other areas (e.g., battery size in EVs, fuel costs, shipping). The raw material cost is also now highly competitive.

What is the biggest hidden cost in magnesium die casting?

The largest hidden costs typically arise from poor Design for Manufacturability (DFM), leading to expensive mold reworks and low production yields. Partnering with a supplier that provides robust DFM analysis is the best way to mitigate this risk.

How can I reduce the cost of my magnesium die casting project?

- Design for Manufacturing: Simplify geometries, avoid unnecessary undercuts, and maintain uniform wall thicknesses.

- Plan for High Volumes: Die casting becomes highly economical at scale, as the high mold cost is amortized over thousands of parts.

- Choose the Right Partner: Select a supplier with expertise in magnesium, in-house secondary operations, and a focus on high yield rates through process control.

Is magnesium die casting sustainable?

Yes. Magnesium components contribute to the sustainability of the final product through lightweighting (reducing energy consumption) and are fully recyclable at the end of their life. Advanced, safer processes like semi-solid casting further enhance its environmental profile.

Conclusion

For OEMs aiming to build lighter, more efficient, and higher-performance products, the goal is not to find the cheapest supplier, but to partner with an experienced, integrated die-casting specialist who can minimize hidden costs and maximize your return on investment through the entire product life cycle.