Aluminum casting die is the cornerstone of efficient and high-quality aluminum die-casting production, and its service life directly impacts production costs, product consistency, and overall operational efficiency for manufacturers.

For many enterprises relying on die-casting processes, frequent replacement of aluminum casting dies not only increases procurement expenses but also causes production downtime and delays. Extending the service life of aluminum casting die has thus become a core goal in the industry. Through in-depth research and practical verification, we have summarized three targeted routines that can extend the life of aluminum casting die by 40%, addressing key pain points in mold use and maintenance. In this article, we will detail these actionable strategies, helping you maximize the value of your aluminum casting die.

Routine 1: Precision-Optimized Design & Material Selection for Aluminum Casting Die

Extending aluminum casting die life hinges on scientific design and high-quality material selection, which form the basis for long-term stable operation. Many manufacturers underestimate the importance of initial design, resulting in premature die failure due to structural flaws.

1.1 Material Selection: The Core of Durability

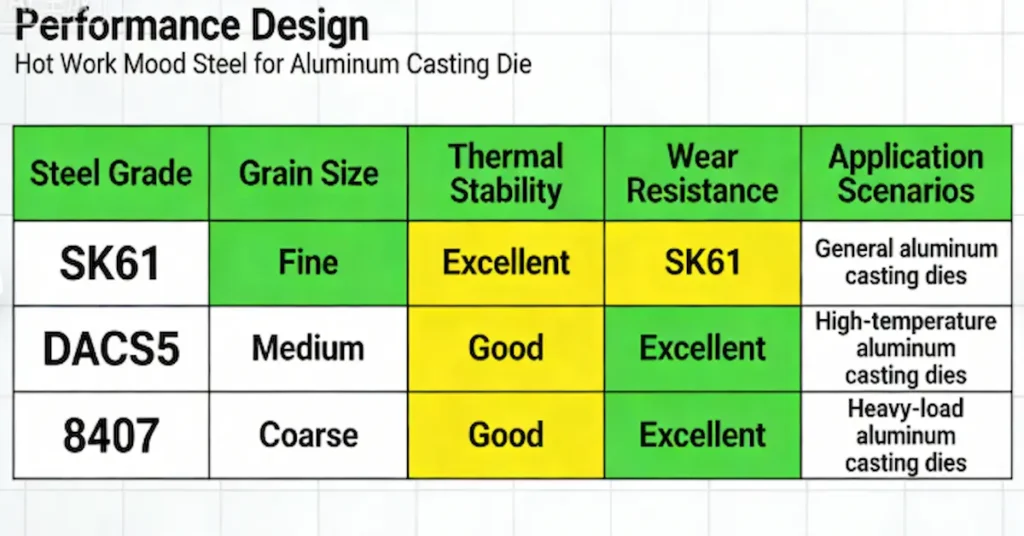

When choosing materials for aluminum casting die cavities, prioritize hot work mold steel with excellent comprehensive performance, such as SK61, DACS5, and 8407. These materials offer fine grain structure, good isotropy, and superior heat treatment capabilities, enabling the aluminum casting die to withstand repeated thermal cycles and molten aluminum erosion. Before processing, conduct rigorous inspections—including appearance checks, metallographic analysis, and ultrasonic flaw detection—to eliminate defective materials that could cause early scrapping of the aluminum casting die. For high-demand applications, consider imported high-performance alloys that comply with the ASTM A681 standard for hot work tool steel to enhance the mold’s wear and thermal fatigue resistance.

1.2 Structural Design: Minimizing Stress & Enhancing Stability

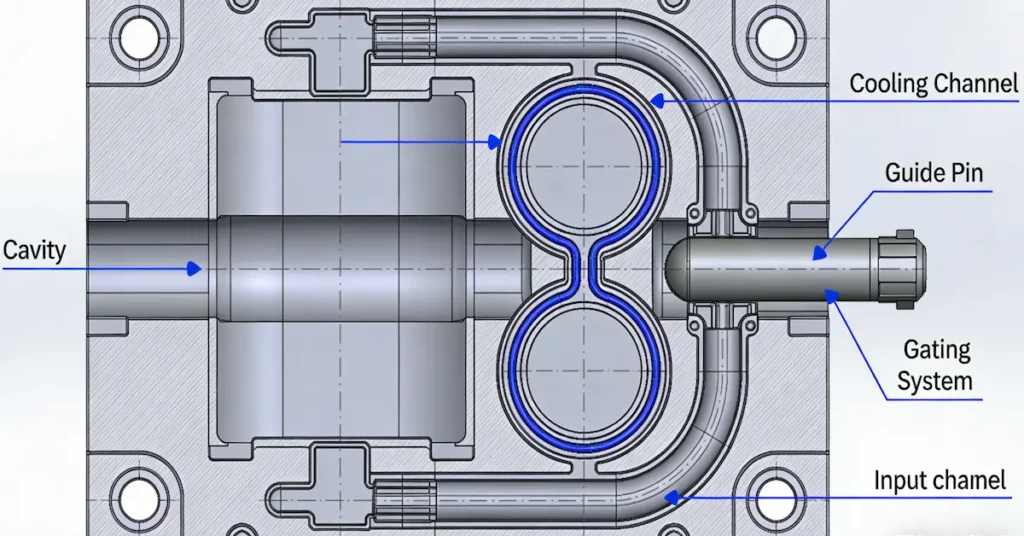

- Pouring System: The inner sprue’s position and size are pivotal. Avoid direct impact of molten aluminum on the core to reduce erosion. Optimize the cross-sectional area to ensure laminar flow of molten aluminum, lowering flow velocity and minimizing cavity impact.

- Forming Parts: Eliminate sharp corners to prevent stress concentration and cracking. For vulnerable components like slender cores, adopt modular splicing structures for easy replacement.

- Template & Guiding Parts: Use integral templates to boost rigidity and load-bearing capacity. Select appropriate tolerance fits and wear-resistant alloy materials for guiding parts, and design replaceable guide inserts to extend maintenance cycles.

- Thermal Balance: Integrate a precision cooling system and mold temperature balancing system to maintain uniform mold temperature, reducing thermal stress and deformation.

- CAD/CAE Simulation: Conduct CAE analysis to optimize temperature, flow, and stress fields, ensuring the aluminum casting die design is robust and reliable.

Routine 2: Rigorous Manufacturing & Heat Treatment Protocols for Aluminum Casting Die

Even with optimal design and materials, subpar manufacturing and heat treatment can undermine the aluminum casting die’s potential lifespan. Strict process control in these stages is essential to enhance structural integrity and performance.

2.1 Precision Manufacturing: Reducing Defects & Residual Stress

- Processing Technology: Unify machining datums to minimize cumulative errors. Use double-sided butt machining for long cooling water holes to ensure coaxiality and surface smoothness. Leverage CAD/CAM technology to improve machining accuracy.

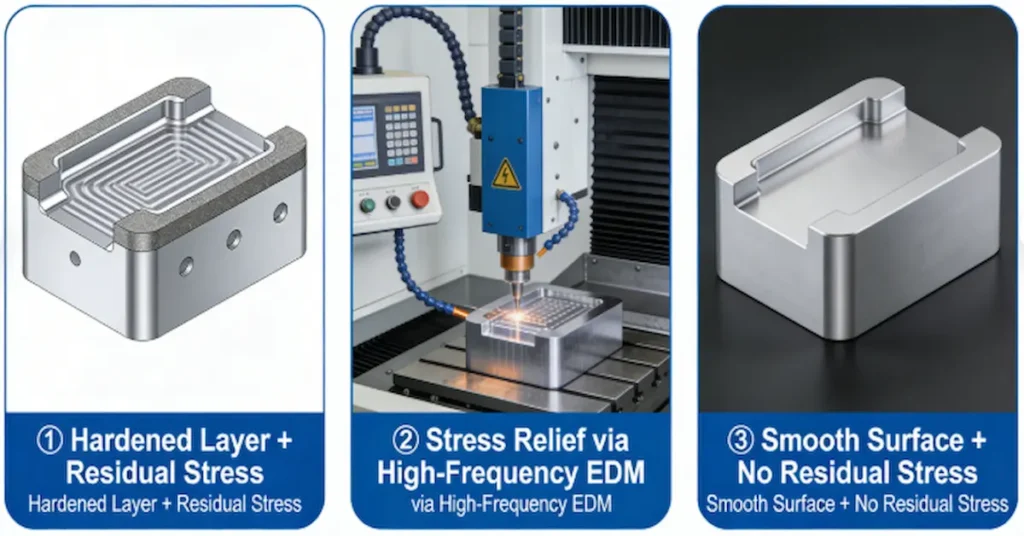

- EDM & Grinding: After electrical discharge machining (EDM), remove the surface hardened layer or relieve stress via high-frequency EDM to eliminate residual stress. During grinding, control coolant volume and avoid excessive feed rates to prevent surface softening and microcracks.

- Weld Repair: Thoroughly clean and preheat the aluminum casting die (440~460℃) with welding rods before welding. Conduct post-weld tempering at 50~80℃ below the original tempering temperature to relieve stress.

- Polishing: Achieve a cavity surface roughness of ≤0.2μm, focusing on narrow seams and deep grooves to reduce flow resistance and improve galling resistance.

2.2 Professional Heat Treatment: Enhancing Hardness & Toughness

- Vacuum Quenching & Tempering: Vacuum quenching prevents decarburization and ensures uniform carbide dissolution. Follow with 2~4 tempering cycles—adjusting temperature based on mold size (higher quenching temperatures for larger molds, lower tempering temperatures) to balance hardness and toughness.

- Stress Relief Tempering: Perform stress relief tempering for new molds after test runs to eliminate residual manufacturing stress.

- Nitriding Treatment: Conduct initial nitriding for qualified new molds, with subsequent treatments based on maintenance schedules. Maintain a substrate hardness of 35~43HRC and a nitriding layer thickness ≤0.15mm, ensuring surface cleanliness for uniform layer formation. Avoid nitriding for severely cracked molds.

Routine 3: Scientific Operation & Maintenance Practices for Aluminum Casting Die

Proper day-to-day use and maintenance are critical to preserving the aluminum casting die’s lifespan. Negligent operation or irregular maintenance can accelerate wear and failure, even for high-quality molds.

3.1 Optimal Operational Parameters

Under the premise of casting quality, minimize molten aluminum pouring temperature, injection speed, and pressure. Shorten high-temperature holding time and use parameter testers to find the optimal process combination—avoid over-reliance on high injection pressure.

3.2 Standardized Pre-Operation & In-Process Care

Uniform Preheating: Use an oil-temperature mold heater for even preheating. Without a heater, conduct test runs to preheat the cavity with molten aluminum, avoiding gas heating (which causes uneven thermal expansion).

- Even Spraying: Focus on deep cavities during lubricant spraying, avoiding prolonged spraying to prevent mold temperature fluctuations.

- Cooling System Maintenance: Regularly inspect and clean cooling channels to prevent blockages, ensuring stable mold temperature.

3.3 Regular Inspection & Proactive Maintenance

- Routine Inspections: Check for cracks, crazing, and erosion. Repair damages promptly via welding; re-nitrify if the nitriding layer is partially damaged.

- Periodic Stress Relief: For aluminum casting dies, perform stress relief tempering after the first 5,000~8,000 cycles, then every 10,000~15,000 cycles. Avoid treatment for severely cracked molds.

- Shutdown Maintenance: For temporary shutdowns, reduce cooling water flow to allow slow cooling. For long-term storage, thoroughly clean, inspect, and maintain the aluminum casting die before storage.

- Operator Training: Train staff on proper operation to prevent mold damage from human error.

Conclusion

Extending the life of aluminum casting die by 40% is not an unattainable goal—it requires a holistic approach integrating precision design, high-quality materials, rigorous manufacturing, professional heat treatment, and scientific maintenance. By implementing these three core routines, manufacturers can significantly reduce aluminum casting die replacement costs, minimize production downtime, and improve overall operational efficiency. Remember, every detail from material selection to daily operation impacts the aluminum casting die’s performance and lifespan. Invest in these practices today to unlock long-term value and maintain a competitive edge in the aluminum die-casting industry.