In the high-stakes world of manufacturing, aluminum die cast products are prized for their strength, lightweight nature, and complexity. However, hidden inefficiencies can quickly erode your profit margins. Whether it’s excessive cycle times or high scrap rates, these costs are often avoidable if you know where to look.

As SEO engineers and manufacturing consultants, we’ve identified the 7 insider secrets that top-tier factories use to slash expenses without compromising on quality.

Optimize Design for High-Efficiency Aluminum Die Cast Parts

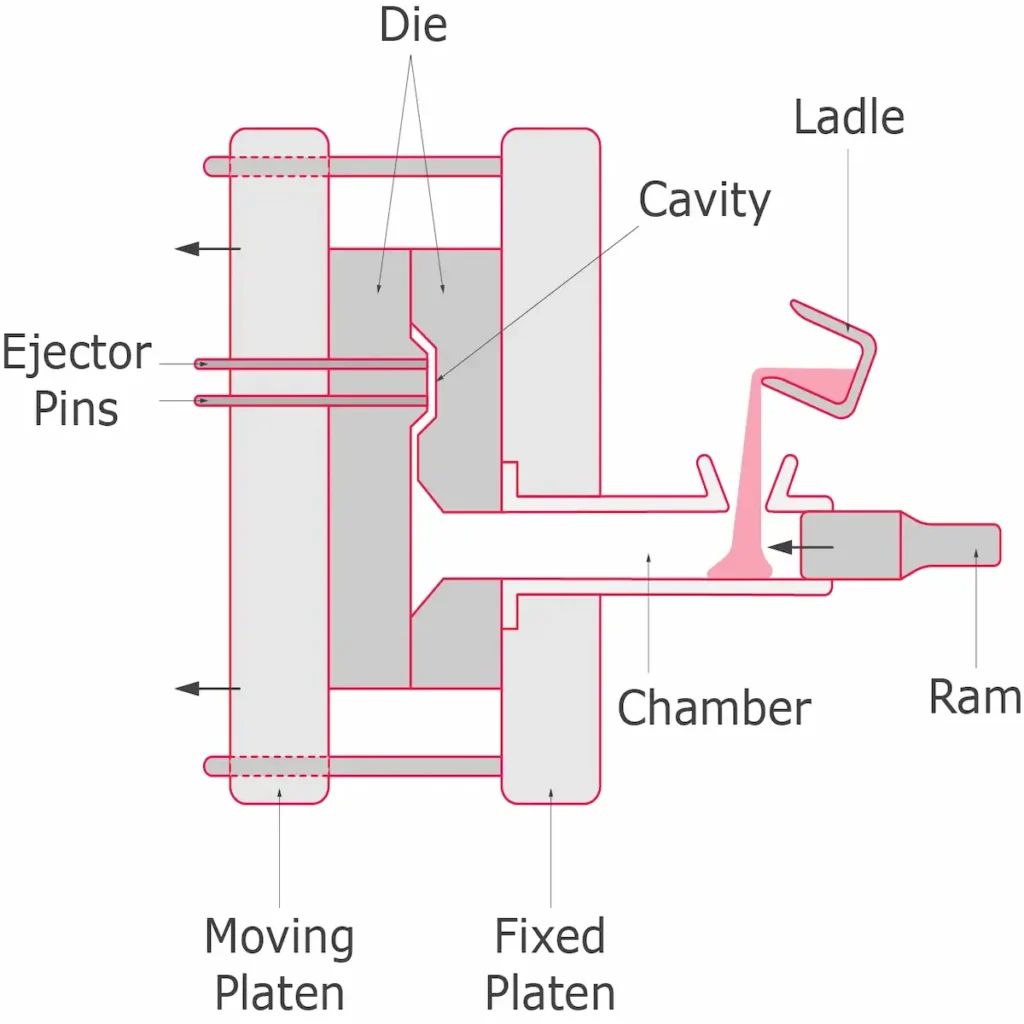

The most effective way to cut costs is to address them before production begins. Design for Manufacturability (DFM) is your strongest weapon in creating a cost-effective aluminum die cast component.

Uniform Wall Thickness: Inconsistent walls lead to “hot spots” and internal porosity. By designing uniform walls, you ensure faster cooling and structural integrity.

Optimal Draft Angles: Providing sufficient draft (typically 1° to 3°) ensures the part ejects smoothly from the mold, reducing tool wear and preventing surface defects that lead to costly rejections.

Strategic Alloy Selection: Beyond the Standard A380

While A380 and ADC12 are the “go-to” alloys for most aluminum die cast projects, they aren’t always the most economical for every specific application.

Secondary Alloys: Using recycled (secondary) aluminum can reduce raw material costs by up to 15%. These alloys offer nearly identical mechanical properties for most commercial applications.

Fluidity vs. Price: Sometimes choosing an alloy with higher fluidity reduces the scrap rate in complex geometries, which saves more money in the long run than buying the cheapest ingot available.

Extend Tooling Life to Lower Aluminum Die Cast Expenses

Your mold is your most expensive asset. Protecting it is key to long-term cost reduction in any aluminum die cast operation.

Modular Inserts: Instead of replacing an entire mold base, use modular inserts for high-wear areas. This allows you to replace only the specific worn sections, saving thousands in tooling reinvestment.

Thermal Management: Use premium H13 steel or specialized coatings to prevent thermal fatigue (heat checking), extending the life of your die by tens of thousands of cycles.

Slash Cycle Times with Advanced Cooling Technology

In high-volume production, every second saved in the aluminum die cast process is pure profit.

Conformal Cooling: Traditional straight-drilled cooling lines leave “hot zones” in the mold. 3D-printed conformal cooling channels follow the part’s shape, reducing cooling time by up to 20%.

Automation: Using robotic arms for extraction and lubrication ensures a consistent, lightning-fast cycle, eliminating the variability and downtime associated with manual labor.

Aim for "Near-Net Shape" to Eliminate CNC Costs

Machining often costs more than the casting itself. The ultimate goal is to produce an aluminum die cast part that requires zero or minimal post-processing.

Tight Tolerances: High-precision molds can achieve “near-net shape,” meaning the part is ready for assembly right out of the machine.

Flash Minimization: Tight-fitting dies and optimized clamping pressure reduce “flash” (excess metal), eliminating the need for manual trimming and secondary de-burring.

Energy Efficiency and Smart Scrap Management

Aluminum requires significant energy to melt. In the aluminum die cast industry, wasted metal is wasted electricity.

Optimize Runner Systems: A poorly designed runner system wastes material. By optimizing the flow, you reduce the amount of “re-melt” material, lowering your energy bill and labor costs.

Vacuum-Assisted Casting: This technology reduces gas porosity, meaning fewer parts end up in the scrap bin, significantly increasing your “First Pass Yield.”

Partner with an Integrated Aluminum Die Cast Vendor

The final secret isn’t technical—it’s logistical. Fragmented supply chains add “hidden” costs like extra shipping, middleman markups, and communication errors.

Single-Source Advantage: Choosing a partner that offers Design + Casting + Machining + Finishing under one roof ensures total accountability.

Total Cost of Ownership: Don’t just look at the “price per part.” Consider the massive savings in logistics and quality control when working with an integrated aluminum die cast expert.

Start Saving on Your Aluminum Die Cast Projects

Slashing costs is a science of incremental gains. By focusing on smart design, tooling longevity, and cycle efficiency, you can maintain a massive competitive edge in the global market.

Ready to optimize your production? Our team of engineers can provide a comprehensive DFM report to identify exactly where your project can save money.