Die Casting Manufacturer for Metal Hardware Industry

We are a professional Metal Hardware die casting manufacturer in China, specializing in high-precision die cast components for metal hardware applications. Our parts are designed to meet the highest standards of mechanical strength, dimensional accuracy, and durability, ensuring reliable performance in every project.. Our services cover the full manufacturing cycle — from early-stage DFM and moldflow analysis to tooling, high-pressure die casting, CNC machining, surface finishing, inspection, and assembly.

We work closely with engineering, procurement, and quality teams to deliver mechanically robust, cost-effective, and dimensionally precise METAL HARDWARE die casting parts tailored to project requirements.

Typical response within 24 hours • Fast DFM feedback before tooling

Why Metal Hardware Requires Die Casting Components

Metal Hardware components demand mechanical strength, dimensional accuracy, durability, and consistent performance to ensure reliable operation in industrial, commercial, and OEM applications. For these reasons, high-pressure die casting has become the preferred manufacturing process for metal hardware parts such as brackets, handles, hinges, structural supports, and enclosures.

Compared with fabricated metal, stamped parts, or plastic components, die-cast metal hardware offers:

- Superior mechanical strength for load-bearing and structural components

- High dimensional stability for precise assembly and fit

- Optimized wall thickness for lightweight yet robust designs

- Enhanced corrosion resistance for long-term durability

- Ability to produce complex geometries with integrated features

- Consistent quality in high-volume production with reduced unit costs

High-pressure die casting enables metal hardware manufacturers to combine strength, precision, and cost efficiency, making it ideal for industrial fixtures, commercial hardware, and OEM metal components.

Engineering Challenges & Metal Hardware Industry Pain Points

OEMs and metal hardware manufacturers typically encounter the followin g engineering and production challenges during design, prototyping, and mass production of metal hardware die cast components:

| Pain Point | Impact on Metal Hardware Production | Engineering Solution |

|---|---|---|

| Structural strength & load-bearing performance | Part deformation, reduced lifespan, assembly failures | High-pressure die casting with optimized wall thickness, ribbing, and structural reinforcement ensures robust mechanical performance |

| Complex geometries & thin walls | Tooling difficulties, warpage, higher scrap rate | Moldflow-driven tooling design, optimized gates/runners, and multi-slide inserts maintain dimensional accuracy and reduce defects |

| Corrosion & environmental resistance | Premature wear, rusting, reduced durability | Alloy selection (aluminum, zinc, magnesium), precision die casting tolerances, and post-casting surface treatments (anodizing, chromate conversion) enhance corrosion resistance |

| Dimensional accuracy for assembly | Misaligned components, poor fit, assembly challenges | DFM tolerance analysis, precision HPDC, and multi-axis CNC finishing ensure precise fit for hinges, brackets, and enclosures |

| Lightweight yet rigid design | Structural deformation, vibration, compromised durability | Topology-informed die casting design, material optimization, and ribbing balance stiffness and weight for reliable performance |

| Surface finish & aesthetic quality | Visible defects, inconsistent finish, higher rejection rates | Integrated surface finishing solutions (brushing, polishing, coating) deliver uniform, high-quality surfaces |

| High-volume consistency & cost control | Unit cost variability, batch inconsistency, downtime | Optimized HPDC parameters, automated process monitoring, and in-line QC deliver consistent quality across large production runs |

How We Solve These Pain Points for Metal Hardware Components

Our Metal Hardware die casting solutions are engineered to deliver mechanical strength, dimensional precision, and high-volume production consistency for brackets, handles, hinges, structural supports, and enclosures.

Early DFM for LED Die Cast Parts

Scope: Early manufacturability & tolerance planning

Key Engineering Actions:

- Wall thickness optimization for structural integrity vs. weight

- Ribbing, bosses & datum structures for rigidity and vibration resistance

- Undercut & deep cavity moldability review

- CNC allowance & datum reference planning for assembly interfaces

Outcome: Fewer late-stage tooling modifications, stable assembly, and faster validation cycles for metal hardware components

Moldflow & Tooling Integration

Scope: Tooling accuracy & porosity control

Key Engineering Actions:

- Gate and runner design for balanced alloy flow

- Venting path design to reduce gas traps and voids

- Thermal balance for dimensional stability during casting

- Ejection & cooling layout for consistent cycle times

Outcome: Improved yield, better surface integrity, and reduced porosity — critical for thin-wall, precision-fit, and load-bearing hardware components

Die Casting + CNC Hybrid Manufacturing

Scope: Net-shape production with precision finishing

Capabilities:

- High-pressure die casting (HPDC) for structural brackets, handles, hinges, and enclosures

- 3-axis, 4-axis, 5-axis CNC for precision assembly interfaces and mounting features

- Controlled datum features & sealing surfaces for mechanical fit and assembly accuracy

Outcome: CNC machining applied only where needed, reducing cost while maintaining tight tolerances and assembly reliability

Finishing & Cosmetic Control Stack

Scope: Surface aesthetics, durability, and corrosion resistance

Processes:

- Bead blasting

- Brushing / Polishing

- Powder coating (optional for protective and aesthetic finish)

- Chromate conversion / Anodizing (for aluminum parts)

- Conductive finishing (optional for EMI shielding in specific hardware)

Outcome: Uniform, high-quality surfaces combined with long-term durability and corrosion resistance for indoor or exposed metal hardware components

Quality, Inspection & Documentation

Scope: Production consistency, traceability & specification compliance

Provided Deliverables:

- 3D CMM dimensional reports

- Material certifications (incoming & outgoing)

- PPAP, FAI, Control Plan, PFMEA

- RoHS / REACH compliance statements (if applicable)

Outcome: Supports OEM audits, environmental compliance, and traceable manufacturing for high-volume metal hardware die cast parts

Low-variance Mass Production Control

Scope: Scaling from prototypes to stable series production

Manufacturing Control Measures:

- SPC (Statistical Process Control) on critical dimensions

- APQP for tooling & process introduction

- CPK tracking for key tolerances

- Lot traceability and serialization options

- Preventive maintenance on dies & CNC machines

Outcome: Uniform, high-quality, mechanically reliable metal hardware components with consistent performance across large production volumes

Materials Used in Metal Hardware Die Casting

Selecting the right material is critical for metal hardware performance, durability, dimensional accuracy, and total manufacturing cost. In die casting, material choice directly affects mechanical strength, corrosion resistance, surface quality, and long-term reliability of hardware components.

While multiple alloys can be used, aluminum alloys remain the primary and most widely applied materials for METAL HARDWARE die casting, followed by zinc and magnesium for specific functional requirements.

Aluminum Alloys Die Casting (Primary Material)

Aluminum die casting is the preferred manufacturing solution for the majority of metal hardware components, including brackets, housings, handles, structural supports, and functional enclosures. It offers an optimal balance of strength, weight, corrosion resistance, and cost efficiency. Common aluminum alloys used for METAL HARDWARE die casting include:

- ADC12 – Excellent castability and dimensional stability, widely used for general-purpose metal hardware

- A380 – Higher mechanical strength and good machinability, suitable for load-bearing and structural hardware components

- EN AC-46000 – European-standard alloy for demanding industrial and commercial hardware applications

Key advantages of aluminum for Metal Hardware Casting:

- High strength-to-weight ratio for structural reliability

- Good corrosion resistance with appropriate surface treatment

- Excellent dimensional stability for precision assembly

- Compatible with anodizing, chromate conversion, powder coating, and painting

- Cost-effective for medium- to high-volume production

Aluminum die casting allows complex geometries, integrated ribs, bosses, and mounting features to be formed in a single process, reducing secondary operations and overall part cost.

Magnesium Die Casting

(Lightweight Hardware Applications)

Magnesium die casting may be considered for metal hardware components where weight reduction is a primary design requirement and mechanical loads are moderate.

Key considerations include:

- Extremely low density and lightweight structure

- Higher raw material and processing cost compared to aluminum

- Increased sensitivity to corrosion without advanced surface protection

Magnesium is typically selected for specialized hardware applications where minimizing weight improves handling, ergonomics, or system-level performance, and where environmental exposure is controlled. Material feasibility is carefully evaluated during the DFM stage to ensure long-term durability and cost justification.

Zinc Die Casting

(Precision Metal Hardware Components)

Zinc die casting is suitable for small-sized, high-precision metal hardware components where dimensional accuracy and surface finish are critical, and structural load requirements are limited.

Typical characteristics of zinc die casting for Metal Hardware:

- Excellent dimensional accuracy and repeatability

- Superior surface finish, ideal for cosmetic or decorative hardware

- Higher density and weight compared to aluminum

- Lower melting temperature, enabling fine feature reproduction

Zinc is commonly used for precision fittings, small brackets, connectors, and decorative metal hardware, especially in indoor or controlled environments. For load-bearing or corrosion-exposed hardware, aluminum alloys are generally preferred.

Common Metal Hardware Components Manufactured by Die Casting & CNC

We supply die cast and machined components for a wide range of LED lighting applications, including:

Structural & Mounting Hardware

- Load-bearing brackets and structural supports

- Mounting bases, frames, and reinforcement components

- Fixed and adjustable mounting interfaces

These components require high mechanical strength, dimensional stability, and fatigue resistance to ensure long-term structural reliability.

Functional Hardware Components

- Handles, grips, and functional housings

- Hinges, joints, and motion-related hardware parts

- Locking components and mechanical interface parts

Die casting enables complex geometries, integrated features, and consistent fit, while CNC machining ensures precise functional interfaces.

Enclosures & Protective Hardware

- Metal enclosures for mechanical protection

- Covers and shields for internal components

- Sealing interfaces and mating surfaces

These hardware parts often demand tight tolerances, smooth surface finishes, and corrosion resistance, especially in industrial or semi-exposed environments.

Precision Hardware & Assembly Interfaces

- Alignment frames and positioning components

- Threaded interfaces, bosses, and datum features

High-pressure die casting combined with multi-axis CNC machining ensures reliable assembly fit and dimensional consistency across production batches.

With integrated DFM, tooling, die casting, CNC machining, surface finishing, and quality control, we ensure OEM customers receive reliable, consistent, and high-quality METAL HARDWARE components for every project.

Engineering DFM & Moldflow Support for Metal Hardware Die Casting Components

Metal Hardware components often involve load-bearing structures, thin-wall designs, complex functional features, and tight assembly tolerances. Early-stage engineering collaboration is critical to reduce tooling cost, prevent production risks, and ensure mechanical performance and dimensional stability throughout mass production. Our DFM and Moldflow support for Hardware die casting focuses on manufacturability, structural integrity, and cost efficiency.

Geometry Feasibility Review

We evaluate critical design factors including:

- Draft angles and wall tapering for high-pressure die casting

- Undercuts, deep cavities, and multi-directional features

- Thin-wall sections for weight reduction without strength loss

- Bosses, ribs, and load-bearing reinforcement structures

- Sharp corners or abrupt transitions affecting metal flow and cooling

- Gating, venting, and ejection path feasibility

- transitions affecting flow and cooling

- Gating, venting, and ejection path feasibility

This review ensures part geometry is casting-friendly, structurally sound, and suitable for high-volume production.

Moldflow & Simulation

Simulation analysis is used to identify and mitigate potential casting risks, including:

- Flow imbalance and incomplete filling

- Cold shuts and weld lines

- Air entrapment and gas pockets

- Porosity concentration zones

- Hot spots and localized shrinkage

- Cooling efficiency and thermal balance across the part

Moldflow-driven decisions improve yield rate, dimensional consistency, and internal integrity of metal hardware components.

Assembly & Integration Support

We ensure die cast metal hardware parts are compatible with:

- Mating components and adjoining assemblies

- Fasteners, threaded inserts, and joining features

- Precision mounting interfaces and datum structures

- Moving or load-transfer interfaces

- Sealing surfaces and functional contact areas

This approach guarantees reliable fit, repeatable assembly, and long-term functional performance.

Design-to-Cost Optimization

Based on DFM and simulation feedback, we propose engineering adjustments that help reduce:

- Cycle time and energy consumption

- Material usage while maintaining structural strength

- Secondary CNC machining requirements

- Surface finishing complexity

- Tooling complexity and maintenance cost

All design optimizations are implemented without compromising mechanical performance, durability, or dimensional accuracy.

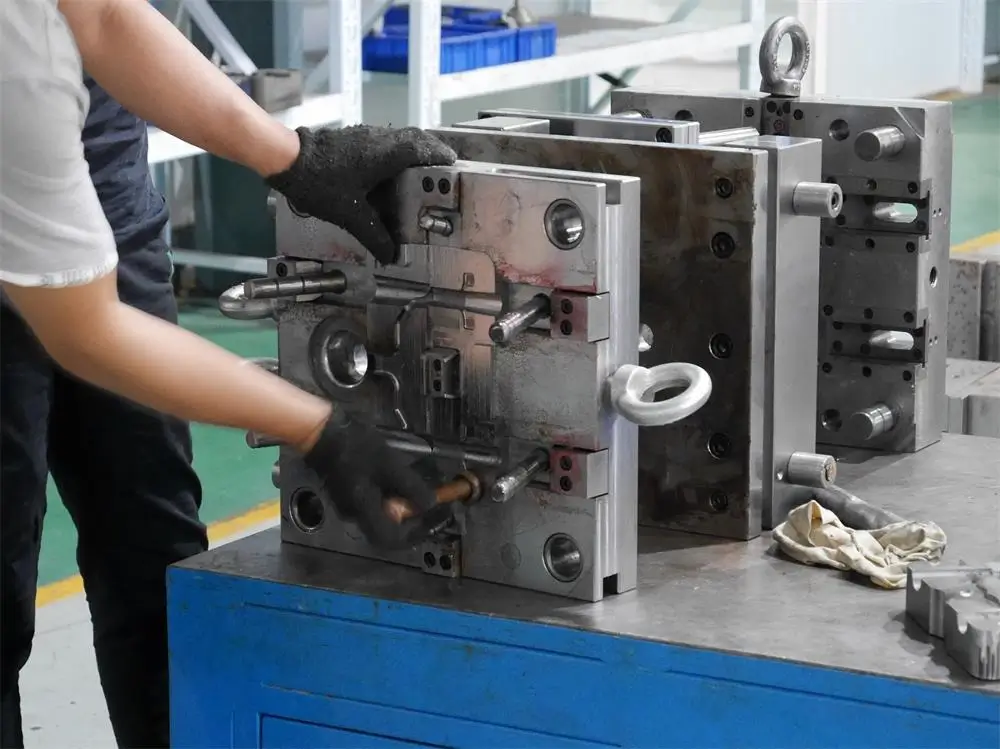

Tooling & Die Casting Manufacturing Process for Metal Hardware parts

IEC Mould integrates tooling design, high-pressure die casting, CNC machining, surface finishing, assembly, and inspection into a fully controlled manufacturing process specifically developed for METAL HARDWARE components.

This integrated approach ensures process stability, dimensional consistency, and repeatable quality, making it well suited for long-term, high-volume production of precision metal hardware die casting parts.

Standard Manufacturing Workflow

- RFQ & drawing review

- DFM & feasibility confirmation

- Moldflow analysis

- Tooling design

- Tool steel selection & fabrication

- Mold trials

- Dimensional inspection

- HPDC mass production

- CNC machining & tapping

- Deburring & cleaning

- Surface finishing

- Final inspection & FAI reports

- Packaging & documentation

- Batch traceability & shipment

Tooling Capabilities

- Multi-slide tooling

- Thin-wall tooling

- Hot runner & vacuum venting

- Rapid cooling circuits

- Cavity pressure monitoring (when required)

- EDM, high-speed milling, and precision grinding

Die Casting Capabilities

- HPDC from 80T to 1250T

- Vacuum assist for porosity reduction

- Water-cooling for dimensional stability

- Process control via temperature & shot monitoring

Secondary Operations

- CNC machining (3/4/5-axis)

- Turning

- Threading (M, UNC/UNF, MJ)

- Reaming & tapping

- Deburring & polishing

- Helicoil insert installation

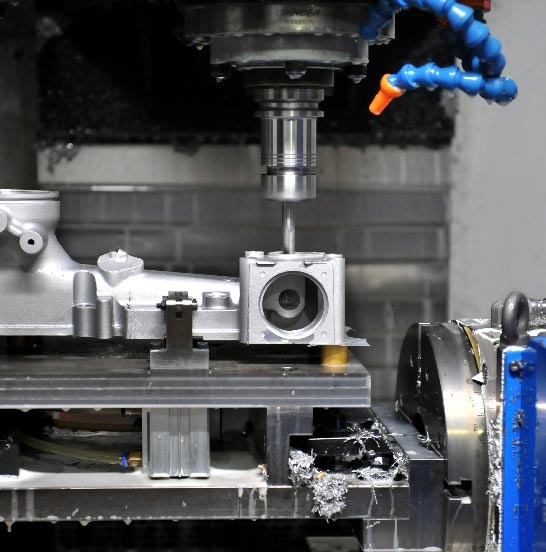

CNC Machining for Metal Hardware Components

CNC machining enhances precision for features that are not achievable by casting alone.

Machining Capabilities

- 3-axis, 4-axis, and 5-axis milling

- Swiss-type turning for small shafts & pins

- Micro-hole drilling

- Tapping and threading

- Helical milling

- ±0.01 mm tolerance control (feature-dependent)

Machinable Features for Medical Parts

- Face & shoulder milling

- Dynamic tool paths for complex contours

- O-ring grooves & sealing features

- Counterbores & countersinks

- Chamfers & radius profiles

- Orthopedic slot features

- Precision bore alignment

Burr-Free & Clean Surface Control

- Automated deburring

- Media tumbling

- Brush polishing

- Electro-polishing (for stainless steel)

- Edge-break control

- Particle-free cleaning

Documentation & Validation

- CMM dimensional reports

- First Article Inspection (FAI)

- PPAP if required

- Traceability records

- Surface roughness measurement

- Material certificates

General Tolerance Guideline for LED Die Casting Parts

The following tolerance ranges serve as general engineering references for metal hardware die casting components. Final tolerances are confirmed based on part geometry, material selection, tooling design, and secondary machining requirements.

| Stage | Feature | Typical Tolerance |

|---|---|---|

| As-Cast (Die Casting Only) | Linear dimensions | ±0.10 – ±0.30 mm |

| Flatness (per 100 mm) | ≤ 0.30 mm | |

| Hole position | ±0.20 mm | |

| After CNC Machining | Linear dimensions | ±0.02 – ±0.05 mm |

| Flatness | ≤ 0.05 mm | |

| Threaded holes | ISO / ANSI standards |

Engineering Note

Tolerance requirements are reviewed during the DFM and tooling design stage to balance manufacturability, performance, and cost. Not all features require tight tolerances — applying CNC machining only where functionally necessary helps optimize overall production efficiency.

Surface Finishing for Hardware Casting Components

We offer surface finishing solutions specifically selected for functional durability, corrosion resistance, and consistent appearance of metal hardware parts.

Anodizing (Type II & III)

- Suitable for aluminum die cast hardware

- Enhances corrosion and wear resistance

- Available in clear, black, and custom colors

- Improves surface hardness for frequently handled parts

Powder Coating

- Uniform and durable coating system

- Good resistance to abrasion and chemicals

- Consistent cosmetic finish for visible hardware

- RoHS-compliant coating options

Sandblasting / Bead blasting

- Creates uniform matte or satin textures

- Improves coating adhesion

- Reduces surface defects visibility

- Commonly used before anodizing or coating

Brushing

- Applied after CNC machining

- Controls surface roughness and directional texture

- Used on exposed or decorative metal hardware surfaces

Chromate conversion

- Applied to aluminum die cast components

- Provides corrosion protection while maintaining conductivity

- Suitable for grounding or contact applications

- RoHS-compliant treatments available

Laser marking

- Permanent marking on aluminum and zinc hardware

- No inks or chemicals, no dimensional impact

- Supports part numbers, logos, and traceability codes

Case Studies (Typical Metal Hardware Applications)

Below are representative metal hardware applications demonstrating how early engineering involvement, die casting optimization, and process integration reduce manufacturing risk, improve part performance, and control total project cost.

Case A: Structural Metal Hardware Housing – Thermal & Strength Balance

Objective:

Achieve efficient heat dissipation while maintaining mechanical strength and dimensional stability in a structural metal hardware housing.

Material:

Aluminum alloy

Manufacturing Method:

High Pressure Die Casting (HPDC) with integrated thin-wall structures

Engineering simulation for flow, solidification, and thermal balance

Key Engineering Focus:

- Thin-wall optimization without compromising rigidity

- Integrated fin and rib structures for heat dissipation

- Controlled wall thickness transitions to minimize shrinkage

- Stable datum surfaces for secondary machining

- Result:

- Improved thermal distribution across the housing

- Reduced localized hot spots

- Enhanced structural stability during long-term use

- Consistent dimensional performance in mass production

Case B:Lightweight Metal Hardware Enclosure with Cosmetic Requirements

Objective:

Reduce overall part weight while maintaining structural stiffness and high-quality surface appearance for visible metal hardware components.

Material:

Aluminum alloy

Manufacturing Method:

Topology-informed HPDC combined with ribbing and boss optimization

Selective CNC machining on functional interfaces

Key Engineering Focus:

- Material reduction through structural rib optimization

- Balanced rigidity and vibration resistance

- Surface quality control for cosmetic-facing areas

- Design-to-cost optimization for high-volume production

- Result:

- Approximately 20% weight reduction

- Improved stiffness-to-weight ratio

- Uniform surface quality suitable for post-finishing

- Lower material usage without sacrificing performance

Why Choose IEC Mould for your Metal Hardware Die Casting parts?

Metal hardware programs demand more than basic manufacturing capacity — they require engineering-led design, structural optimization, process stability, and long-term supply reliability. IEC Mould’s metal hardware die casting solutions are developed to support OEM and contract manufacturing programs from early development through stable high-volume production.

We provide a fully integrated metal hardware die casting solution covering the complete production lifecycle:

- DFM – Manufacturability review, tolerance planning, wall thickness optimization, and cost-focused design for metal hardware parts

- Tooling – Moldflow-driven die design with balanced gating, optimized venting, and multi-slide tooling for complex geometries

- Die Casting – High-pressure aluminum die casting delivering strength, dimensional stability, and repeatable quality

- CNC Machining – Multi-axis precision machining for functional interfaces, threads, and tight-tolerance features

- Surface Finishing – Anodizing, powder coating, bead blasting, brushing, chromate conversion, and laser marking

- Assembly –Mechanical fastening, insert installation, sub-assembly, and fit verification

This one-stop manufacturing approach reduces engineering risk and supply chain complexity, shortens development cycles, and ensures consistent quality and cost control across all metal hardware die casting components — from initial samples to long-term series production.

FAQ About LED Die Casting

What types of metal hardware parts are suitable for die casting?

Die casting is ideal for metal hardware parts requiring complex geometry, tight tolerances, thin walls, and high-volume production, such as housings, brackets, covers, and structural components.

Which materials are commonly used for metal hardware die casting?

Aluminum alloys (such as ADC12 and A380) are the most widely used for metal hardware due to their strength, dimensional stability, corrosion resistance, and cost efficiency.

What tolerances can be achieved in metal hardware die casting?

As-cast tolerances typically range from ±0.10 to ±0.30 mm. After CNC machining, critical features can achieve tolerances of ±0.02 to ±0.05 mm, depending on part design.

When is CNC machining required after die casting?

CNC machining is applied to functional interfaces, threaded holes, sealing surfaces, and datum features where tighter tolerances or assembly accuracy are required.

What is the typical tooling lead time for metal hardware die casting?

Tooling lead time typically ranges from 4 to 8 weeks, depending on part complexity, size, and tooling structure.

Start Your Hardware Casting Project

Upload your drawings or samples to receive professional DFM feedback. Our engineers will review your LED design and provide feasibility analysis, tooling recommendations, and production guidance.