Casting Die Casting Manufacturer for Marine Industry

The marine industry requires components that can operate reliably under harsh conditions such as saltwater exposure, high humidity, vibration, and long-term outdoor environments. Our casting die casting solutions are engineered to meet these demanding requirements while ensuring precision, durability, and cost efficiency.

As a professional casting die casting manufacturer in China, we provide full-service support from DFM and Moldflow analysis to tooling, high-pressure die casting, CNC machining, surface finishing, inspection, and assembly. We support OEMs, marine equipment manufacturers, boat builders, and offshore system suppliers with stable, high-quality mass production.

Typical response within 24 hours • Fast DFM feedback before tooling

Why the Marine Industry Uses Casting Die Casting

Marine equipment manufacturers face constant pressure to improve performance, reduce weight, and ensure long-term reliability. Casting die casting offers several advantages compared with fabrication or traditional machining:

- Complex shapes produced in one piece to reduce assembly

- High dimensional accuracy for reliable installation

- Lightweight metal structures for fuel efficiency and performance

- Stable quality for medium to high-volume production

- Excellent surface quality for protective coatings

- Cost-effective manufacturing for long product life cycles

Casting die casting is widely used for marine housings, structural brackets, mounting components, and precision hardware.

Marine Industry Challenges & Casting Die Casting Solutions

Marine applications operate in extremely harsh environments. From saltwater exposure to vibration and long-term outdoor use, poor design or improper manufacturing can lead to early failure, leakage, or high maintenance costs.

Our engineering team identifies potential risks during the early stage and optimizes the design and manufacturing process to ensure reliable casting die casting performance.

| Marine Industry Challenge | Potential Risk | Our Casting Die Casting Solution |

|---|---|---|

| Saltwater corrosion | Surface damage, reduced service life | Select corrosion-resistant alloys and apply anodizing, powder coating, or chromate conversion for long-term protection |

| Waterproof & sealing requirements | Leakage, equipment failure, warranty risk | Precision CNC machining for sealing surfaces and O-ring grooves, combined with low-porosity casting die casting control |

| Weight reduction requirements | Structural weakness or deformation | DFM optimization with rib reinforcement and wall thickness balance to achieve lightweight yet strong structures |

| Vibration and mechanical loads | Cracks, fatigue, or dimensional instability | Structural simulation and reinforced design to improve strength and durability |

| Complex shapes and integration needs | High machining cost and assembly errors | High-precision casting die casting to produce near-net-shape components and reduce secondary operations |

| Outdoor and UV exposure | Coating failure and surface degradation | Surface preparation and durable finishing systems designed for long-term outdoor performance |

By addressing these challenges at the design and manufacturing stage, we help marine equipment manufacturers achieve longer product life, improved reliability, and stable mass production.

Materials for Marine Casting Die Casting

Different marine applications require different material properties. Our casting die casting capability supports multiple alloys to meet strength, weight, corrosion, and precision requirements.

Aluminum Alloy Die Casting (Primary Material)

Common alloys: A380, ADC12, AlSi10Mg

Most widely used for:

- Marine equipment housings

- Pump and motor housings

- Structural brackets and mounts

- Lighting and control enclosures

Advantages:

- Lightweight with good strength

- Good corrosion resistance

- Suitable for anodizing and powder coating

- Ideal for outdoor and salt-spray environments

Magnesium Alloy Die Casting

Common alloys: AZ91D,AM60B,AM50A

Applied in:

- Weight-sensitive marine equipment

- Portable marine devices

- Lightweight structural components

Advantages:

- Extremely low density

- High strength-to-weight ratio

Surface protection is applied to ensure durability in marine environments.

Zinc Alloy Die Casting

Common alloys: Zamak 3,Zamak 5,ZA-8

Used for:

- Precision marine hardware

- Locks, hinges, connectors

- Small complex components

Advantages:

- Excellent dimensional accuracy

- Smooth surface finish

- Ideal for thin-wall and intricate designs

- Cost-effective for high-volume production

Typical Marine Casting Die Casting Applications

We supply die casting and machined components for a wide range of Marine applications, including:

Boat & Yacht Components

Deck brackets, mounting bases, structural supports, hardware components.

Marine Equipment Housings

Control box enclosures, communication housings, sensor housings, waterproof aluminum casings.

Power & Fluid Systems

Pump housings, motor housings, valve bodies, mounting frames.

Marine Electronics Protection

Navigation equipment housings, lighting enclosures, junction boxes

With integrated DFM, tooling, die casting, CNC machining, surface finishing, and quality control, we ensure OEM customers receive reliable, consistent, and high-quality Marine Hardware components for every project.

Engineering DFM & Moldflow Support for Marine Hardware Die Casting Components

Marine components must withstand saltwater, humidity, vibration, and long-term outdoor exposure. These conditions require strong structures, reliable corrosion protection, and stable dimensional accuracy.

Early DFM and Moldflow support help optimize wall thickness, control porosity, improve sealing performance, and reduce casting tooling risk. Our engineering focuses on reliable marine casting die casting solutions for durable and cost-efficient mass production.

Geometry Feasibility Review

We evaluate critical design factors including:

- Draft angles and wall tapering for high-pressure die casting

- Undercuts, deep cavities, and multi-directional features

- Thin-wall sections for weight reduction without strength loss

- Bosses, ribs, and load-bearing reinforcement structures

- Sharp corners or abrupt transitions affecting metal flow and cooling

- Gating, venting, and ejection path feasibility

- transitions affecting flow and cooling

- Gating, venting, and ejection path feasibility

This review ensures part geometry is casting-friendly, structurally sound, and suitable for high-volume production.

Moldflow & Simulation

Simulation analysis is used to identify and mitigate potential casting risks, including:

- Flow imbalance and incomplete filling

- Cold shuts and weld lines

- Air entrapment and gas pockets

- Porosity concentration zones

- Hot spots and localized shrinkage

- Cooling efficiency and thermal balance across the part

Moldflow-driven decisions improve yield rate, dimensional consistency, and internal integrity of metal hardware components.

Assembly & Integration Support

We ensure die cast metal hardware parts are compatible with:

- Mating components and adjoining assemblies

- Fasteners, threaded inserts, and joining features

- Precision mounting interfaces and datum structures

- Moving or load-transfer interfaces

- Sealing surfaces and functional contact areas

This approach guarantees reliable fit, repeatable assembly, and long-term functional performance.

Design-to-Cost Optimization

Based on DFM and simulation feedback, we propose engineering adjustments that help reduce:

- Cycle time and energy consumption

- Material usage while maintaining structural strength

- Secondary CNC machining requirements

- Surface finishing complexity

- Tooling complexity and maintenance cost

All design optimizations are implemented without compromising mechanical performance, durability, or dimensional accuracy.

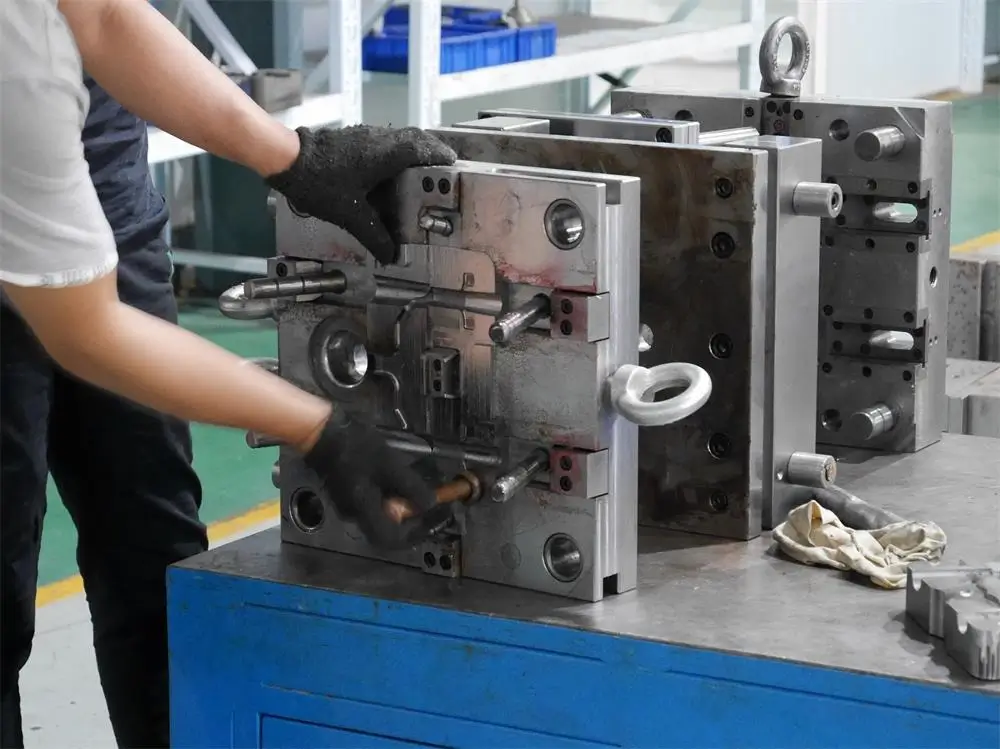

Tooling & Casting Die Casting Manufacturing Process for Marine Components

IEC Mould provides a fully integrated manufacturing system for marine casting die casting, including tooling engineering, high-pressure die casting, CNC machining, surface treatment, assembly, and quality inspection.

This controlled process ensures low porosity, stable dimensions, and reliable surface protection to meet the corrosion resistance, sealing performance, and durability required for marine environments. It is ideal for long-term, high-volume production of precision marine components used in boats, marine equipment, and outdoor applications.

Standard Manufacturing Workflow

- RFQ & drawing review

- DFM & feasibility confirmation

- Moldflow analysis

- Tooling design

- Tool steel selection & fabrication

- Mold trials

- Dimensional inspection

- HPDC mass production

- CNC machining & tapping

- Deburring & cleaning

- Surface finishing

- Final inspection & FAI reports

- Packaging & documentation

- Batch traceability & shipment

Tooling Capabilities

- Multi-slide tooling

- Thin-wall tooling

- Hot runner & vacuum venting

- Rapid cooling circuits

- Cavity pressure monitoring (when required)

- EDM, high-speed milling, and precision grinding

Die Casting Capabilities

- HPDC from 80T to 1250T

- Vacuum assist for porosity reduction

- Water-cooling for dimensional stability

- Process control via temperature & shot monitoring

Secondary Operations

- CNC machining (3/4/5-axis)

- Turning

- Threading (M, UNC/UNF, MJ)

- Reaming & tapping

- Deburring & polishing

- Helicoil insert installation

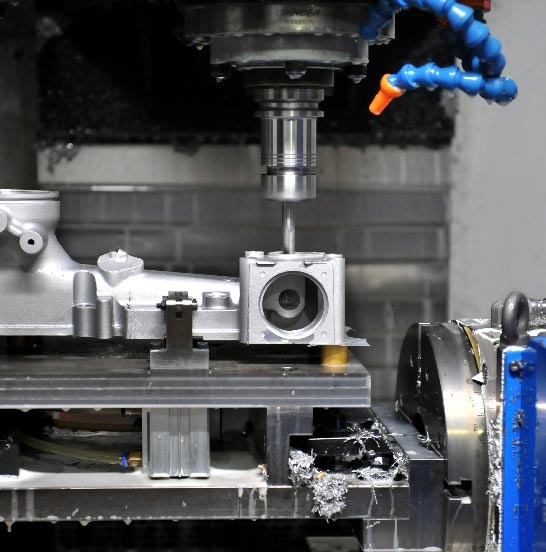

Precision CNC Machining for Marine Casting Die Casting Components

CNC machining is used to achieve critical features that require higher precision than casting alone, especially for sealing interfaces, threaded connections, and assembly surfaces in marine applications.

Secondary machining ensures tight tolerances, improved flatness, and accurate alignment, helping marine casting die casting components achieve reliable waterproof performance, stable assembly, and long-term durability in harsh marine environments.

Machining Capabilities

- 3-axis, 4-axis, and 5-axis milling

- Swiss-type turning for small shafts & pins

- Micro-hole drilling

- Tapping and threading

- Helical milling

- ±0.01 mm tolerance control (feature-dependent)

Machinable Features for Medical Parts

- Face & shoulder milling

- Dynamic tool paths for complex contours

- O-ring grooves & sealing features

- Counterbores & countersinks

- Chamfers & radius profiles

- Orthopedic slot features

- Precision bore alignment

Burr-Free & Clean Surface Control

- Automated deburring

- Media tumbling

- Brush polishing

- Electro-polishing (for stainless steel)

- Edge-break control

- Particle-free cleaning

Documentation & Validation

- CMM dimensional reports

- First Article Inspection (FAI)

- PPAP if required

- Traceability records

- Surface roughness measurement

- Material certificates

General Tolerance Guideline for Marine Casting Die Casting Parts

The following tolerance ranges are provided as general engineering references for marine casting die casting components. Final tolerances are determined based on part structure, material selection, environmental requirements, and functional needs such as sealing performance and assembly accuracy.

| Stage | Feature | Typical Tolerance |

|---|---|---|

| As-Cast (Die Casting Only) | Linear dimensions | ±0.10 – ±0.30 mm |

| Flatness (per 100 mm) | ≤ 0.30 mm | |

| Hole position | ±0.20 mm | |

| After CNC Machining | Linear dimensions | ±0.02 – ±0.05 mm |

| Flatness | ≤ 0.05 mm | |

| Threaded holes | ISO / ANSI standards |

Engineering Note

Tolerance requirements are evaluated during the DFM and tooling development stage to ensure reliable sealing, stable assembly, and long-term performance in marine environments. Critical areas such as sealing surfaces, O-ring grooves, and mounting interfaces are selectively CNC machined to achieve the required precision while maintaining cost-efficient production.

Die Casting Surface Finishing for Marine Environment

We offer surface finishing solutions specifically selected for functional durability, corrosion resistance, and consistent appearance of metal hardware parts.

Anodizing (Type II & III)

- Suitable for aluminum die cast hardware

- Enhances corrosion and wear resistance

- Available in clear, black, and custom colors

- Improves surface hardness for frequently handled parts

Powder Coating

- Uniform and durable coating system

- Good resistance to abrasion and chemicals

- Consistent cosmetic finish for visible hardware

- RoHS-compliant coating options

Sandblasting / Bead blasting

- Creates uniform matte or satin textures

- Improves coating adhesion

- Reduces surface defects visibility

- Commonly used before anodizing or coating

Brushing

- Applied after CNC machining

- Controls surface roughness and directional texture

- Used on exposed or decorative metal hardware surfaces

Chromate conversion

- Applied to aluminum die cast components

- Provides corrosion protection while maintaining conductivity

- Suitable for grounding or contact applications

- RoHS-compliant treatments available

Laser marking

- Permanent marking on aluminum and zinc hardware

- No inks or chemicals, no dimensional impact

- Supports part numbers, logos, and traceability codes

Case Studies (Typical Marine Casting Die Casting Applications)

The following examples demonstrate how early engineering collaboration, casting die casting optimization, and integrated manufacturing help marine customers improve product reliability, reduce production risk, and control overall project cost.

Case A: Waterproof Marine Control Housing – Sealing & Corrosion Protection

Objective:

Develop a marine equipment housing with reliable waterproof performance and long-term resistance to saltwater and outdoor exposure.

Material:

Aluminum alloy

Manufacturing Method:

High Pressure Casting Die Casting (HPDC)

Precision CNC machining for sealing interfaces

Protective surface treatment for marine environment

Key Engineering Focus:

- Low-porosity casting to support sealing performance

- Flatness control on sealing surfaces and O-ring grooves

- Uniform wall thickness to reduce shrinkage and distortion

- Surface preparation for anodizing or powder coating

Result:

- Stable IP-level sealing performance

- Improved corrosion resistance in salt-spray conditions

- Reduced leakage risk and field failure

- Consistent dimensional stability in mass production

Case B: Lightweight Marine Equipment Enclosure – Strength & Weight Optimization

Objective:

Develop a marine equipment housing with reliable waterproof performance and long-term resistance to saltwater and outdoor exposure.

Material:

Aluminum alloy

Manufacturing Method:

Topology-optimized casting die casting with reinforced ribs

Selective CNC machining for mounting interfaces

Key Engineering Focus:

- Structural rib design for stiffness with reduced material usage

- Balanced wall thickness to prevent deformation

- Vibration resistance under dynamic operating conditions

- Design-to-cost optimization for volume production

Result:

- Approximately 15–20% weight reduction

- Improved strength-to-weight ratio

- Stable performance under vibration and mechanical load

- Lower material consumption and improved production efficiency

Why Choose IEC Mould for Your Marine Casting Die Casting Components

Marine projects require more than just manufacturing capacity — they demand engineering-driven design, corrosion-resistant structures, precise dimensional control, and long-term reliability in harsh marine environments.

IEC Mould’s marine casting die casting solutions are engineered to support OEMs, boat builders, and marine equipment manufacturers from early-stage design and tooling development to stable, high-volume production. Our integrated approach ensures durable, seawater-resistant components with consistent quality for the full product lifecycle.

We provide a fully integrated die casting solution covering the complete production lifecycle:

- DFM – Manufacturability review, tolerance planning, wall thickness optimization, and cost-focused design for metal hardware parts

- Tooling – Moldflow-driven die design with balanced gating, optimized venting, and multi-slide tooling for complex geometries

- Die Casting – High-pressure aluminum die casting delivering strength, dimensional stability, and repeatable quality

- CNC Machining – Multi-axis precision machining for functional interfaces, threads, and tight-tolerance features

- Surface Finishing – Anodizing, powder coating, bead blasting, brushing, chromate conversion, and laser marking

- Assembly –Mechanical fastening, insert installation, sub-assembly, and fit verification

This one-stop manufacturing approach reduces engineering risk and supply chain complexity, shortens development cycles, and ensures consistent quality and cost control across all metal hardware die casting components — from initial samples to long-term series production.

FAQ About LED Die Casting

What materials are commonly used for marine casting die casting?

Aluminum, zinc, and magnesium alloys are typically used for marine components, providing corrosion resistance, lightweight performance, and high dimensional accuracy. Copper and bronze are used in marine environments but usually with other casting methods.

Can casting die casting parts withstand saltwater and outdoor conditions?

Yes. With proper alloy selection and surface treatments such as anodizing, powder coating, or chromate conversion, marine casting die casting parts can achieve excellent corrosion resistance and long-term durability.

Are waterproof housings possible with casting die casting?

Absolutely. Precision CNC machining, low-porosity casting, and controlled sealing surfaces allow the production of reliable waterproof housings suitable for marine equipment.

What is the typical lead time for Cast tooling and production?

Tooling lead time usually ranges from 4–8 weeks depending on part complexity. Mass production lead times depend on volume, but our integrated process ensures stable and predictable delivery.

Can IEC Mould handle high-volume marine casting die casting production?

Yes. Our fully integrated approach — from engineering and tooling to casting, CNC machining, surface finishing, and inspection — supports high-volume production while maintaining consistent quality and dimensional stability.

Start Your Marine Casting Parts

Upload your drawings or samples to receive professional DFM feedback. Our engineers will review your design and provide feasibility analysis, tooling recommendations, and production guidance.