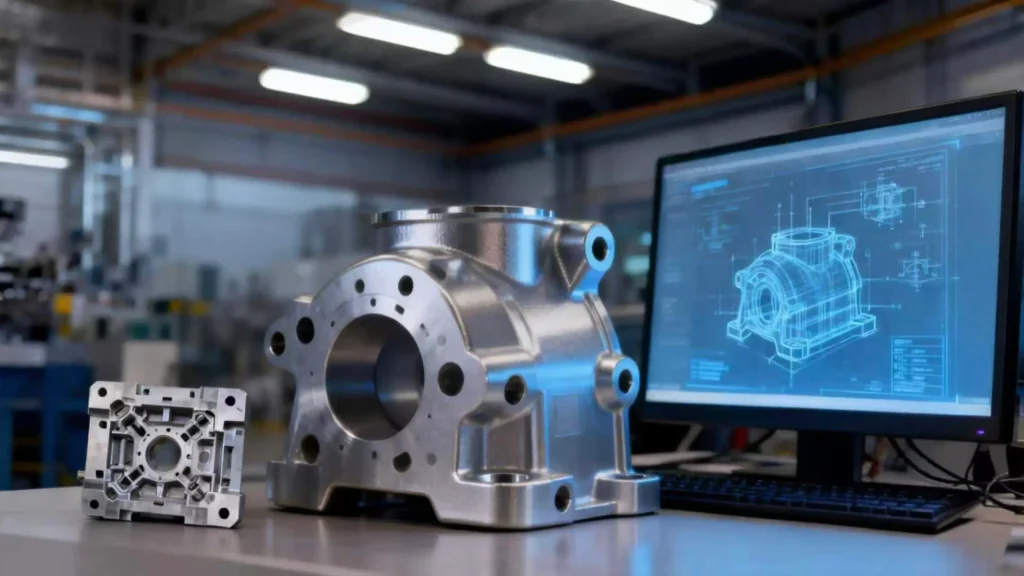

In the relentless pursuit of lightweighting and performance, magnesium die casting design stands out as a premier manufacturing solution. Its exceptional strength-to-weight ratio, superior damping capacity, and excellent EMI shielding make it ideal for automotive, aerospace, and 3C electronics. However, unlocking its full potential hinges on one critical factor: an impeccable magnesium die-casting design that accounts for its unique properties relative to more common alloys like aluminum.

A successful magnesium die casting design is not merely an adaptation of an aluminum blueprint. It requires a dedicated approach that respects the unique flow, solidification, and mechanical properties of magnesium alloys. To underscore these fundamental differences, consider the following key design parameter comparisons:

Aluminum vs. Magnesium Die Casting Design Key Parameters

Comparison of critical design parameters for magnesium and aluminum alloy die casting processes.

| Design Parameter | Magnesium Alloy | Aluminum Alloy | Rationale & Implication |

|---|---|---|---|

| Typical Wall Thickness | 1.0mm - 4.0mm | 1.5mm - 5.0mm | Magnesium's superior fluidity allows for thinner walls, enabling greater weight reduction without sacrificing fillability. |

| Minimum Draft Angle | 1° - 1.5° | 1.5° - 2° | Magnesium's lower shrinkage force on the die allows for slightly less draft, offering more design flexibility. |

| Minimum Fillet Radius | 0.5mm - 1.0mm | 1.0mm - 1.5mm | Larger radii are always better, but magnesium's fluidity can accommodate slightly tighter corners, improving stress distribution. |

| Rib Thickness Ratio | 50% - 70% of nominal wall | 60% - 80% of nominal wall | Thinner ribs are possible with magnesium, aiding in achieving lightweight, rigid structures while minimizing sink marks. |

| Tolerance Capability | ±0.002 mm/mm (High Precision) | ±0.003 mm/mm (Standard) | Magnesium's lower thermal expansion and reduced die wear can contribute to more consistent, tighter tolerances. |

| Note: These values are typical guidelines. Actual design parameters should be determined in consultation with your die-casting supplier, taking into account alloy selection, part geometry, and application requirements. | |||

A design optimized for the process is the cornerstone of part integrity, cost-efficiency, and project success. This ultimate guide to magnesium die casting design will empower you with ten golden rules to create components that excel in performance, manufacturability, and cost-effectiveness.

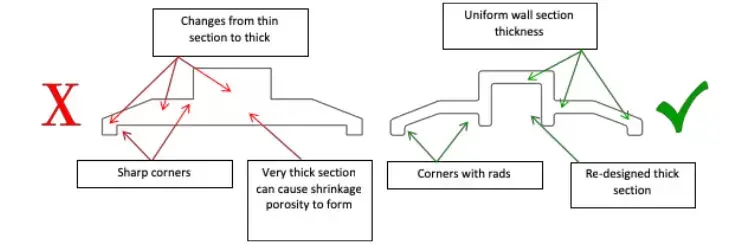

Rule 1: Champion Uniform Wall Thickness

The single most critical rule in magnesium die casting design is maintaining consistent wall thickness. Magnesium’s rapid solidification makes it particularly sensitive to variations, which create hot spots leading to shrinkage porosity, distortion, and internal stress. Aim for walls between 1.5mm and 4.0mm, leveraging magnesium’s superb fluidity to go thinner than other metals where possible.

Case in Point: A leading manufacturer faced warping and porosity in a large, thin-walled 5G base station shield. By collaborating on a DFM review, the magnesium die casting design was revised to ensure a perfectly uniform wall thickness of 2.0mm and strategic rib placement. This eliminated defects and resulted in a lightweight, structurally sound component that met stringent EMI shielding requirements.

Rule 2: Apply Generous Draft Angles

Draft angles are non-negotiable for part ejection and tooling longevity. For magnesium die casting design, insufficient draft can lead to drag marks, scoring, or even part seizure due to the alloy’s tendency to adhere to steel surfaces. As a baseline, incorporate a minimum of 1° of draft per side on external walls and 1.5° to 2° on internal walls and deep ribs.

Rule 3: Utilize Large Radii and Fillets

Sharp corners are the enemy of durable castings. They act as stress concentrators, impede metal flow, and can become initiation points for cracks—a significant concern for magnesium alloys. Incorporating generous radii at all intersections significantly improves structural integrity, enhances fluidity, and reduces turbulence during filling. A good practice is to use a minimum fillet radius of 0.5-1.0mm, and larger wherever the design permits. This principle is critical for high-integrity magnesium die casting design, especially in demanding sectors like automotive and aerospace.

Rule 4: Strengthen with Intelligent Ribbing

Instead of increasing wall thickness to gain stiffness, use well-designed ribs. This is key to achieving lightweight, rigid structures. Ribs should be designed with a height no greater than three times the nominal wall thickness and a base thickness between 50% and 80% of the adjoining wall. These dimensional guidelines are supported by foundational research in lightweight structural design. For in-depth analysis and advanced structural principles, engineers often refer to authoritative resources such as the SAE International technical paper. Our engineering team utilizes advanced simulation software to validate rib design and overall part stiffness as part of our die casting engineering.

Rule 5: Design Functional Bosses for Assembly

Bosses for screws and fasteners must be designed to withstand assembly forces without cracking. To prevent sink marks on the opposite surface, the boss’s wall thickness should not exceed 80% of the nominal wall. Use gussets (triangular supports) to connect bosses to nearby walls, dramatically increasing their strength without creating thick sections, a crucial tactic in robust magnesium die casting design.

Rule 6: Strategically Design Holes and Windows

While magnesium’s fluidity allows for the casting of small holes and openings, thoughtful design is essential. Through-holes are preferable to blind holes. If blind holes are necessary, limit their depth to no more than 2-3 times their diameter.

Case in Point: Achieving high-precision, as-cast holes for connector pins in a magnesium automotive sensor housing was a major challenge. Through advanced simulation and precise thermal management of the core pins, the process was optimized to cast multiple holes with a positional accuracy of ±0.05mm, eliminating the need for secondary drilling and reducing unit cost by 15%.

Rule 7: Integrate Features, Minimize Post-Processing

Maximize the net-shape advantage of die casting by integrating features directly into the tool. This includes functional elements like logos, nameplates, datum locators, and electrical connector slots. For cosmetic or sealing surfaces, specify the required finish level early.

Rule 8: Plan for Efficient Mold Filling and Cooling

A great part design facilitates a great mold design. Avoid long, thin sections that are difficult for metal to fill before cooling. Be mindful of how the part geometry will affect thermal balance in the die; localized thick sections can create hot spots that slow cycle times and promote defects. This consideration is paramount in effective magnesium die casting design.

Rule 9: Leverage Simulation-Driven Iteration

Never finalize a design without numerical simulation. Advanced software can model molten metal flow, heat transfer, solidification, and part stress. This virtual prototyping phase is indispensable for identifying and correcting potential defects before cutting steel. This proactive approach is a key part of our rapid prototyping and die casting engineering offerings, de-risking your project before production begins.

Rule 10: Embrace Early and Collaborative DFM

The ultimate golden rule for successful magnesium die casting design is to involve your die casting partner at the earliest concept stage. A formal Design for Manufacturability (DFM) review is the most effective cost and risk-reduction tool. Experts can analyze your model against all nine previous rules, suggest optimizations for your specific alloy.

Conclusion: From Design to Reality

Adhering to these ten golden rules for magnesium die casting design bridges the gap between a good idea and a flawless, high-performance component. It’s a disciplined approach that balances ambitious engineering with the realities of physics and manufacturing, ensuring your magnesium parts are not only lighter and stronger but also more reliable and cost-effective to produce.

Are you ready to optimize your next magnesium component?

Submit your design for a complimentary, confidential DFM analysis from our engineering team and experience the difference that expert-guided magnesium die casting design can make.